Fiberglass Decks

All our fiberglass decks start with the installation of 1/2” AC Aruco plywood. Glue and screws 8” OC are used to fasten the plywood. This greatly reduces the possibility of cracking joints and nail pops. Shop routed Azek trim boards are fastened to the outside edge of the fiberglass deck and chamfer strips along interior walls. Once the plywood installation is complete the entire surface is sanded, joints and screw holes are polyester puddy filled. A primer coat of polyester resin is applied to the deck surface to ensure a full bond to the AC plywood substrate. Once cured the surface is sanded and Owens Corning 2 OZ fiberglass chopped strand mat is cut and set in place. All seams are feathered to minimize visible overlaps. Fiberglass is ran 8” up interior walls and door openings are fiberglass pan flashed. A secondary resin saturation coat is then applied to the fiberglass using the hand layup method. After a complete cure, the fiberglass deck is trimmed sanded and coated with colored non slip gelcoat.

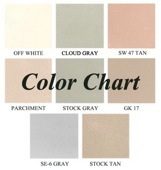

Fiberglass deck coating has a life span of 30 to 40 years providing the fiberglass deck is re-gel coated every ten years. Multiple color selections are available for our non slip gel coat finish. Finish fiberglass deck colors must be of a light tone, darker colors will result in excessive surface temperature, blistering, and pealing of the gel coat. Custom colors must be checked with our supplier regarding approved application. Custom colors are not guaranteed from the supplier for a 100% match. Job site temperature may effect the final color outcome of the fiberglass deck.

Benefits of Using Eastern Fiberglass Company

See Deck Preparation and Deck Drawings for more information

Fiberglass deck coating has a life span of 30 to 40 years providing the fiberglass deck is re-gel coated every ten years. Multiple color selections are available for our non slip gel coat finish. Finish fiberglass deck colors must be of a light tone, darker colors will result in excessive surface temperature, blistering, and pealing of the gel coat. Custom colors must be checked with our supplier regarding approved application. Custom colors are not guaranteed from the supplier for a 100% match. Job site temperature may effect the final color outcome of the fiberglass deck.

Benefits of Using Eastern Fiberglass Company

- 7 PLY 1/2” ARUCO STAGGERED SEAMS

- ZINC COATED SCREWS (NO NAILING)

- ALL SCREW HOLES / JOINTS PUDDY FILLED

- AZEK ROT FREE DRIP EDGE W/ V GROOVE

- 1.5” CHAMFER STRIPS INSTALLED

- 2 OZ 76” FIBERGLASS MAT (NOT 1.5 oz)

- ALL OVERLAPS FRAYED

- DECK FULLY SANDED PRIOR TO GEL COAT

- PUMICE NON SLIP TEXTURE IN GEL COAT FINISH

See Deck Preparation and Deck Drawings for more information